The automotive sector is a high-paced manufacturing environment, which requires precision and durability in every component. From intricate interior elements to strong bumpers and state-of-the-art lighting components, the automotive sector requires an injection moulding process that can operate efficiently at high volumes, without ever compromising on quality.

Traditional automotive components are often moulded from high-performance polymers, engineered polymers or composites, and are expected to meet strict quality standards. Automotive components must often possess both strength and lightweight characteristics, with precision and tight tolerances, while maintaining a pleasing aesthetic finish.

Injection moulding stands as a pivotal process in meeting these benchmarks, and having the right machinery is a crucial factor in maintaining your competitive edge. For businesses within the automotive industry, ensuring the perfect balance of efficiency and precision in production is a necessity, and BOLE is well-placed to serve your needs.

PERFECTLY SUITED TO THE AUTOMOTIVE SECTOR:

BOLE DK Series

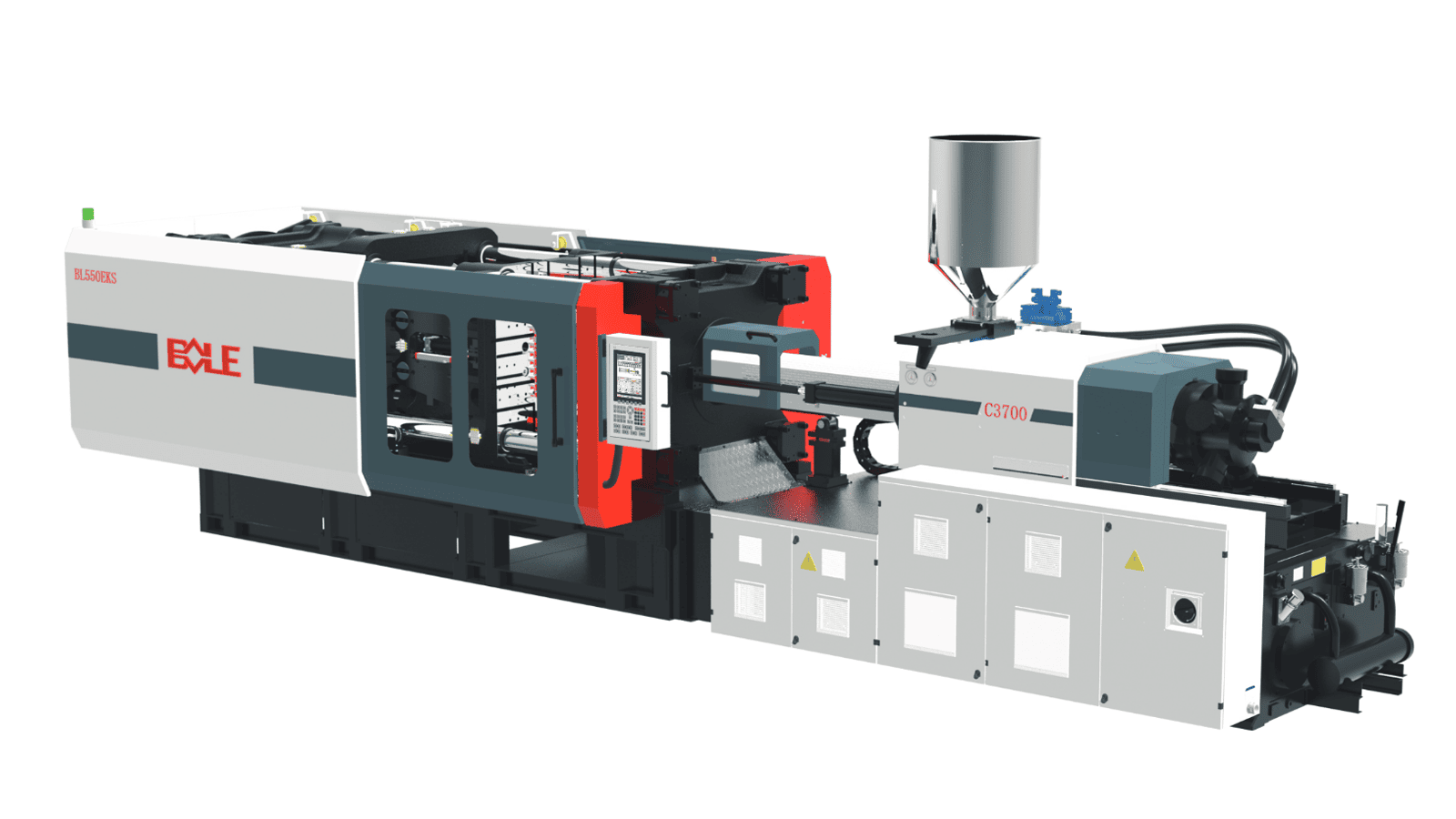

BOLE EKS Series

BOLE EKW Series

Sector-specific advantages:

- Large space between tie bars

- Large platen area

- Variable size injection units for small/large shot weights

- Small footprint

- Multi-component configurations available

- Fully integrated options for automation combinations & host processors systems

- Energy efficient

The world’s largest manufacturers trust Bole